Impellor

A fan or impellor forms the main part of the separation of grain from trash. The principle is very effective for most Australian grain separation requirements. High capacity flow can be achieved with one important optional element: Precision Feed.

Precision Feed

A variable speed, power driven roller that gives a consistent flow of grain across the airflow. Intermittent grain flow causes variations in sample quality, and Precision Feed prevents grain slugs from blocking the gravity feed-in, keeping the grain flowing, even in difficult conditions.

The flow of grain is variable via a VFD which regulates the feed roller speed.

NO SIEVES or SCREENS!

The bane of cleaning grain, the ISM is free of these mechanical nightmares. The simple principle of grain falling across an airstream can clean up your sample.

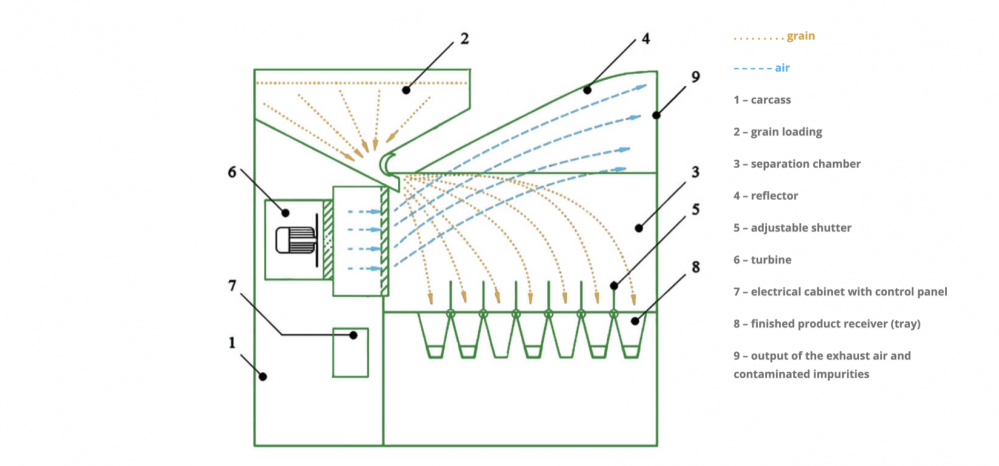

Variable air flow

Adjustable airflow to suit all required samples. ISM machines don't just choke off the air; they featured variable frequency drives (VFD) which control the fan speed to reduce your power requirement.

Variable compartments

The drop zone for good grain progressing to lighter grain then trash can be fully adjusted. Seven drop chutes have adjustable catch flaps which can give you a fine adjustment to keep or reject your finished sample.

240V Plug & Play

New owners are confident within a few minutes of startup thanks to 240V Plug & Play - a feature available on most models.

Plug into a power source

Close gravity feed chute

Set fan going at mid-range

Fill hopper and maintain to minimum level with a ready to continue supply

Slowly open gravity feed chute

Check sample at various outlets

Adjust in-flow & fan speed to give desired results.

Gravity Feed vs Precision Feed

Constant grain flow is critical to high performance. Grain slugs & intermittent flow can cause issues with any grain cleaning device.

Quality, high speed cleaning requires a Precision Feed, you’ll love it.

Pre-Cleaner Option

To help in very trashy conditions a continuous mesh belt, pre-cleaner can be fitted to the top hopper. This design quickly carries larger material to discharge chutes while grain falls through the mesh. Various mesh sizes are available. The mesh rotating speed is adjustable via a variable frequency drive (VFD) & an LED display shows your current speed.